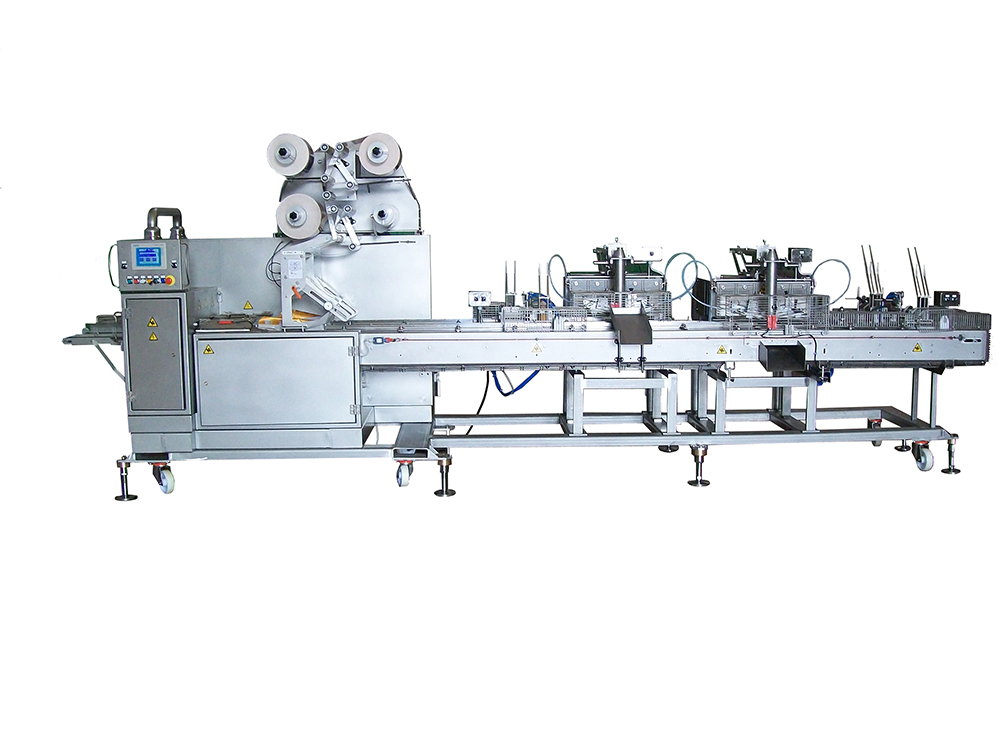

PFW6.2S

PFW6.2S

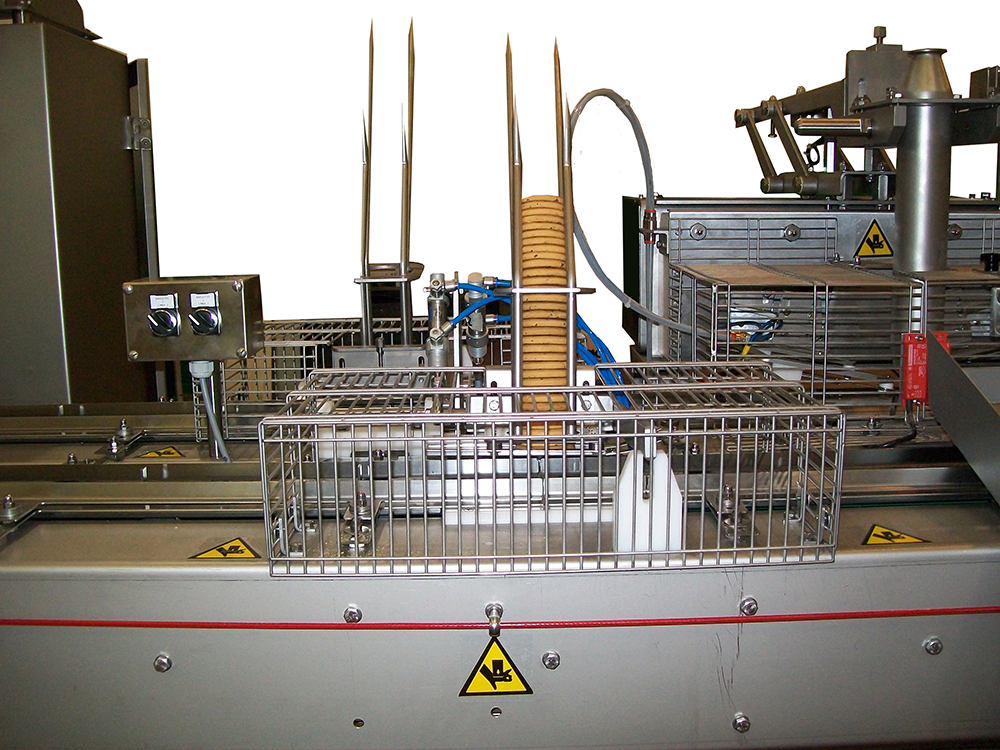

PFW6.2S is the most advanced filled biscuits flow wrapping machine, especially designed for ice cream sandwich but suitable for several other applications.

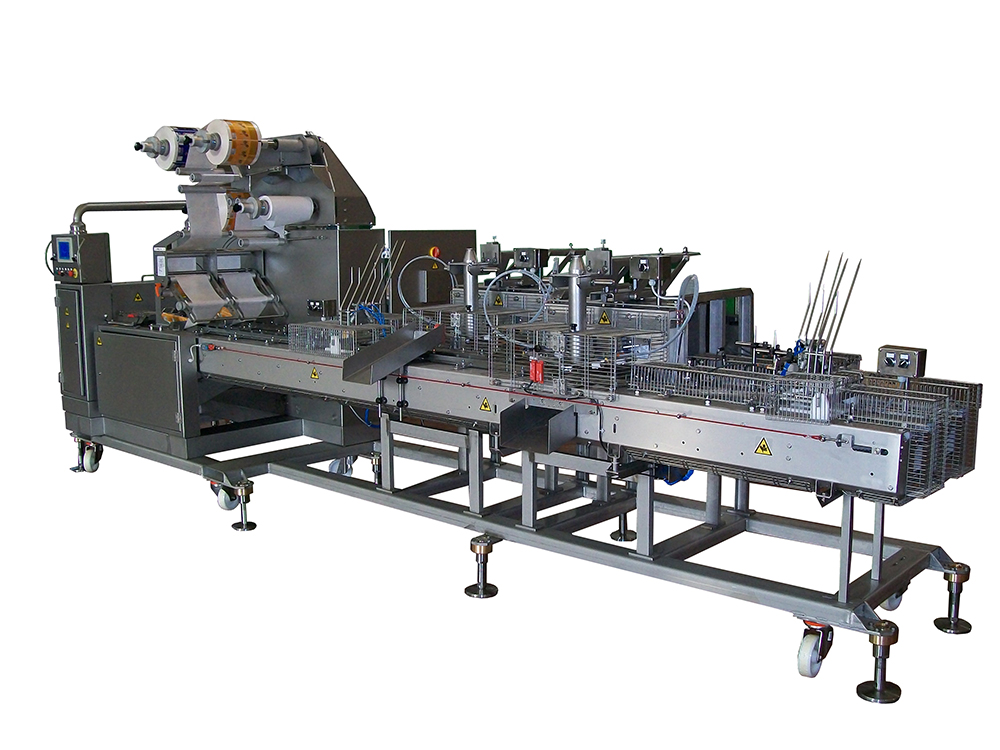

This horizontal form fill and seal machine is a multi lane flow wrap, with two synchronized infeed conveyors with extrusion head and double wire cut group.

Its compact design and easy to use interface and settings lead to substantial savings in term of surface required and control operators. Furthermore low linear speed provides an higher degree of packaging efficiency.

The main features of this machine are:

- Compact construction in AISI304 stainless steel with built-in electric cabinet.

- Lower frame with wheels for easy moving.

- Fully servo-assisted machine.

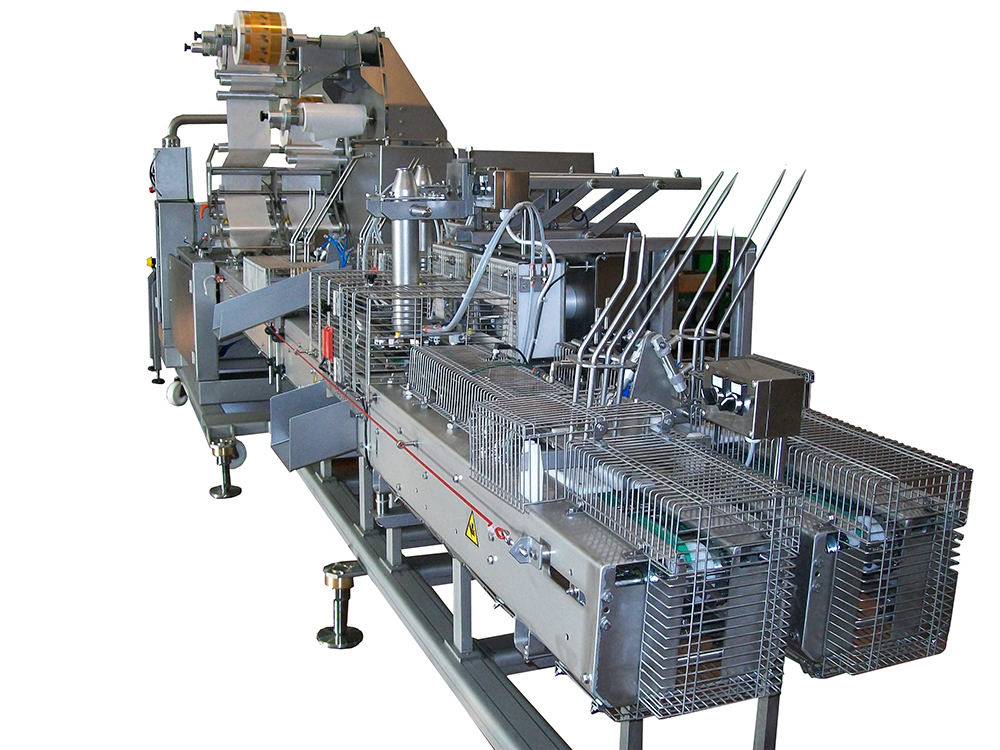

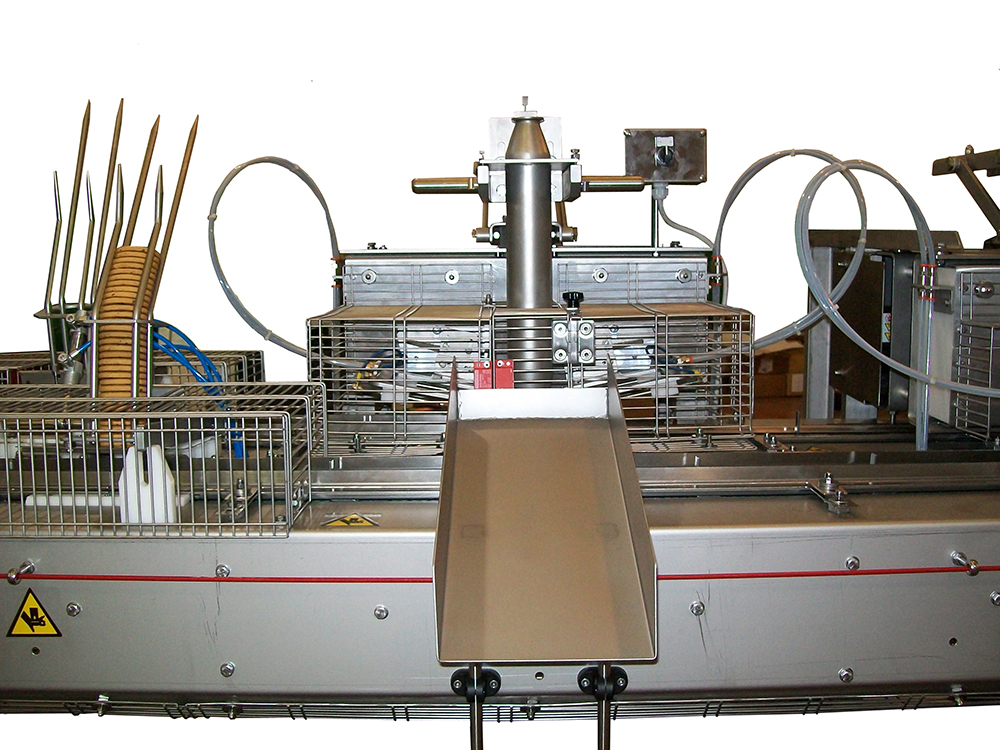

- Two or three couple of sealing rollers with temperature control and product length managed via PLC.

- Double rotary jaws group per line with a standard width of 150mm.

- Double reel holder with self centering cones and electric eye.

- FESTO pneumatic components and Siemens electronic devices integrated in the rear part of the machine.

- Double wire cut group with servo-assisted transmission.

- Stainless steel frame for extractable extruder.

- Frame for biscuit dispenser with pneumatic movement.

Velocità: fino a 220 ppm, con doppia.La velocità della macchina dipende dal prodotto

Dimensioni del prodotto: fino a 300x100x60mm**

Specifiche del portabobine: fino a L=300mm – Øi=85mm – Øe=300mm Peso max=35kg**

Rete elettrica:tensione rete da 220 a 460 V – Frequenza di rete 50/60 Hz

Gruppo pneumatico:aria compressa a 6 bar

Dimensioni della macchina: 2750X850X1720mm – Peso approx: 750kg

Le dimensioni della macchina possono variare in funzione di richieste

Bancale: L=1500mm – Piano di lavoro=1000mm**

Rulli saldanti: Saldatura standard=15mm**

Masse saldanti:Larghezza std=150mm – Lama semplice o a zig zag

**Disponibili soluzioni personalizzate su richiesta